Aerogas Engine Overhaul

Presently PT6A-21, -25A /25 C, -27,-28,-41,-42 Engines which powers Beechcraft King Air C-90, B 200, BE 100, Twin otter DHC 6, Harbin Y 12 and Pilatus PC-6 and PC-7 aircrafts, are overhauled.

Turboprop Engine

Pratt & Whitney Turboprop Engines

- Complete repair & overhaul of Pratt & Whitney PT6A series engines.

- Hot Section Inspection (HSI) & repair of all hot section components like Compressor Turbine blade replacement and balancing, weld repair of combustion chamber liner, exit-ducts, shroud housings and shroud grinding to achieve precise tip clearance etc.

- Repair and reassembly of compressor turbine stator assembly.

- Overhaul, Testing & cleaning of Fuel nozzles.

- Bleed Valve Repair, Overhaul & Testing.

- PT6A Engine component level Repair, Overhaul & Painting. Pay by hour engine maintenance option for valued customers having fleet of aircraft.

- Customized Gas Generator Section and Power Section Repair, Overhaul & Testing.

- Light overhaul.

- In field troubleshooting.

- ECTM.

Balancing Machine

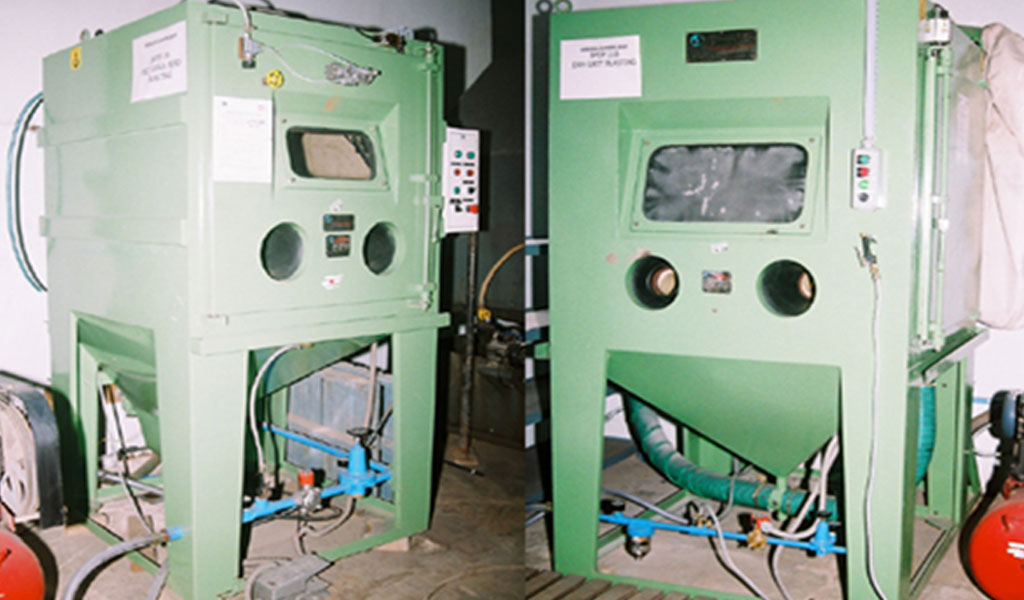

Turbine Engine Cleaning facility

Wet and Dry Blasting Equipment

The cleaning facility is established with an exhaust system for environmental control which enables the cleaning of various components of the Engine before taking up for NDT and further inspection.

Riveting Machine

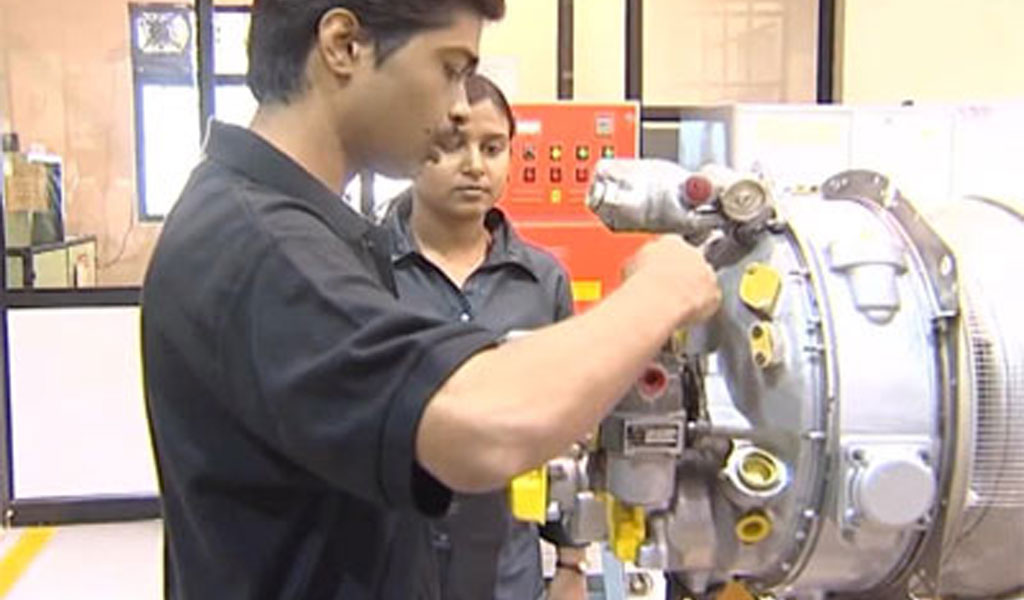

Turbo Prop Assembly

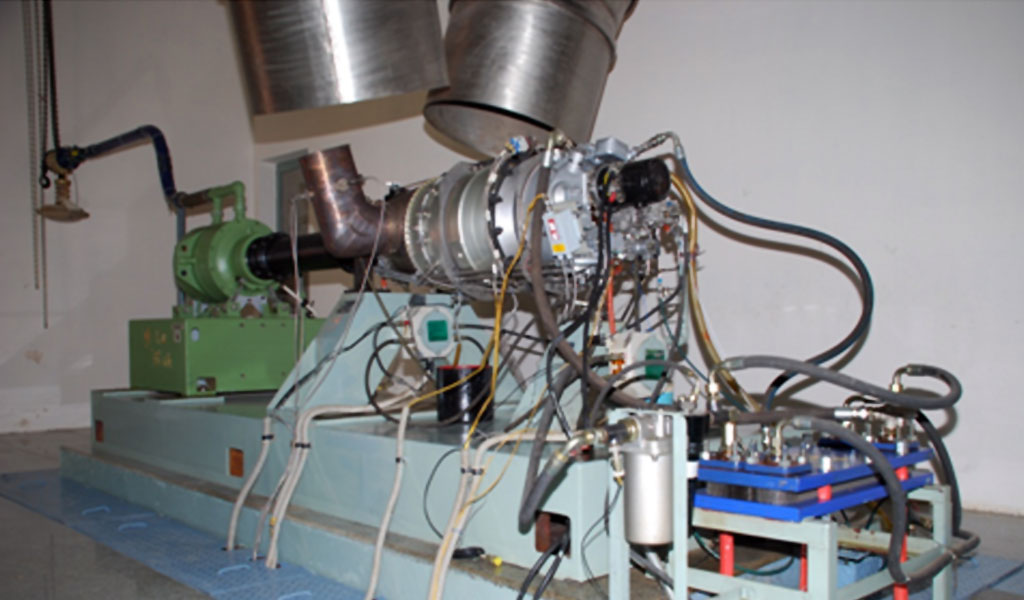

PT6A Turbine Engine Testbed

The engine overhaul facility is unique and will obviate customers in India to send the Engines all the way to Australia or Canada, and is economical to get the Engines overhauled in the shortest period. The facility aslo helps to take up Hot Section Inspection, called for at half life period for these Engines with TBO of approx. 4000 hrs.

VAPL’s turbo prop overhaul facility houses the Test bed which is equipped with a Schenck Dynamo meter D – 1200E which can take-up Engines up to 1200 KW. The test bed is equipped with ACES analyzer for measuring vibration levels both on Reduction Gearbox and Accessories gear Box of the Engines. A sophisticated data acquisition System is provided in the control room for digital display of all the pressures, temperatures at various points in the lubrication circuit and intermediate and exhaust temperatures of the Engine. Paharpur Cooling Tower enables to cool the water for the Dynamo meter and Alfa Laval Oil Cooler for cooling the engine oil. The test bed is provided with sound proofing panels for absorption of noise.

The main assembly and inspection area is dust free and has controlled environment. The shop is equipped with a Standards room for gauge control and Bearing Hospital to check the condition of the main roller and ball bearings of the Engines.